Aluminum AlSi10Mg

Aluminum AlSi10Mg is an alloy with good casting properties and is used for cast part designs with thin walls and complex geometry. The alloying elements of silicon and magnesium result in high strength and hardness. The alloy also features good dynamic properties and can be used for parts subjected to high stress loads. Parts in Aluminum AlSi10Mg are ideal for applications that require a combination of good thermal distribution and low weight.

Aluminum AISi10Mg Properties

- High Strength

- Hardness

- Good Dynamic Properties

Applications

Cobalt Chrome MP1

Cobalt Chrome MP1 will produce parts in a cobalt-chrome-molybdenum-based super alloy. This class of super alloy is characterized by having excellent mechanical properties like strength, hardness, corrosion resistance, and temperature resistance. Theses alloys are commonly used in biomedical applications such as dental and medical implants. They are also ideal for high-temperature engineering applications like those in aerospace engines.

Properties

- High Strength, temperature, and corrosion resistance.

- Mechanical properties improve with increased temperature up to 500-600 °C.

- Chemistry conforms to the composition UNS R31538 Of high carbon CoCrMo alloy.

- Nickel-Free (< 0.1 % nickel content).

- Fulfills the mechanical and chemical specifications of ISO 5832-4 and ASTM F75 for cast CoCrMo implant alloys.

Applications

- High-temperature engineering applications (e.g., turbines and medical implants).

Maraging Steel MS1

Maraging Steel MS1 is a martensite steel with increased hardenability. Its chemical composition corresponds to U.S. classification 18% Ni Maraging 300, European 1.2709, and German X3NiCoMoTi 18-9-5. This kind of steel is characterized by having excellent strength combined with high toughness. Parts are easy to machine and polish after the building process. MS1 can be easily post-hardened to more than 50 HRC.

Properties

- Easy to Machine

- Age Harding Up To Approximately 54 HRC

- Good Thermal Conductivity

Applications

- Series Injection Molding and High-Volume Production

- Other Tooling Applications (e.g., Aluminum Die Casting)

- High-Performance Parts

Stainless Steel GP1

Stainless Steel GP1 is characterized by having good mechanical properties, especially excellent ductility in the laser-processed state. The chemical composition corresponds to U.S. classification 17-4, European 1.4542, and German X5CrNiCuNb16-4. Stainless Steel is widely used in a variety of engineering applications. This material is ideal for many part-building applications such as functional metal prototypes, small series products, individualized products, or spare parts.

Properties

- Good Mechanical Properties

- Excellent Ductility

Applications

- Engineering Applications Including Functional Prototypes

- Small Series Products

- Individualized Products or Spare Parts

- Parts Requiring Particularly High Toughness and Ductility

Stainless Steel PH1

Stainless Steel PH1 is characterized by having excellent mechanical properties, especially in the precipitation-hardened state. The chemical composition conforms to the compositions of 15-5 PH, DIN 1.4540, and UNS S15500. This type of steel is widely used in a variety of medical, aerospace, and other engineering applications requiring high hardness and strength. This material is ideal for many part-building applications such as functional metal prototypes, small series products, individualized products, or spare parts.

Properties

- Very High Strength

- Easy to Harden Up to Approximately 45 HRC

Applications

- Engineering Applications Including Functional Prototypes

- Small Series Products

- Individualized Products or Spare Parts

- Parts Requiring Particularly High Strength and Hardness

Titanium Ti64

Titanium Ti64 (Ti6Al4V) is a well-known alloy characterized by having excellent mechanical properties and corrosion resistance combined with low specific weight and biocompatibility. The ELI version (extra-low interstitials) has a particularly high purity level.

Properties

- Light Weight With High Specific Strength (Strength Per Density)

- Corrosion Resistance

- Biocompatibility

- Laser-Sintered Parts Fulfill Requirements Of ASTM F1472 (for Ti6Al4V) and ASTM F136 (for Ti6Al4V ELI) Regarding Maximum Impurities

- Very Good Bio-Adhesion

Applications

- Aerospace & Engineering Applications

- Biomedical Implants

DMLS Finishing

Fathom offers a multitude of in house finishing options for DMLS parts. Our experts can also manage any outsource finishing needs for your DMLS parts. Parts built on a DMLS machine have a raw, rough finish comparable to a fine investment cast. The surface roughness is approximately 350 R a- µ inch or R a-µm 8.75, or a medium-turned surface. This surface roughness can be improved all the way up to 1 R a- µ inch or R a-µm 0.025, qualifying as a super mirror finish. There are several processes available that can be used to achieve the desired surface roughness or finish.

Abrasive Blast (Grit & Ceramic) //

Abrasive blasting is the operation of forcibly propelling a stream of abrasive material (media) against a surface under high pressure to smooth a rough surface. Abrasive blasting services are included standard for all DMLS projects. If a DMLS part with a raw appearance is desired, this should be noted when submitting your quote request. Abrasive blasting with grit and ceramic media provides a satin, matte finish of approximately 150 R a- µ inch or R a-µm 24. This finish is mostly, but not a 100% uniform finish.

Shot Peen //

Shot peening is a process used to produce a compressive, residual stress layer that can modify the mechanical properties of metals. Shot peening done by impacting the surface of the part with various media. The impact force is sufficient enough to create plastic deformation. It is similar to blasting, except that it operates by the mechanism of plasticity rather than abrasion. Peening a surface spreads it plastically causing changes in the mechanical properties of the surface. Shot peening can increase fatigue life up to 1000 percent, depending on the part geometry, part material, shot material, shot quality, shot intensity, and shot coverage. Shot peening is used primarily by foundries for de-burring or descaling surfaces in preparation for additional post-processing.

Optical Polish //

Optical polish is best finishing option for parts that have a low number of geometries that are not tolerance dependent. Optical polishes are extremely cost effective and the best way to achieve a brilliant finish. At least .003 in. to .010 in. of surface material will removed during the process depending upon part geometry. This is mainly due to the surface porosity of DMLS metals. It is imperative that designers or engineers consult with Fathom prior to building, as specific surfaces may need to be offset with additional material in order to ensure part dimension and integrity after post-processing. Optical polishing is not ideal for large batches as it can result in inconsistent finish from part to part.

Electrochemical Polishing //

Electrochemical polishing, also referred to as electro polishing, is a finishing process that removes material from metal parts through polishing, passivation, and deburring. Electrochemical polishing is often described as the reverse of electroplating. Electroplating is used to grow a thick, protective oxide layer on the surface of a material rather than polish. Electrochemical polishing is the reverse, removing materials to create a clean surface. The process may be used in lieu of abrasive fine polishing in micro structural preparation and is an inexpensive option for DMLS projects that are not tolerance dependent. Electro polishing creates a bright, uniform finish. The success of electro polishing depends on the degree of preparation of the treated surfaces.

Abrasive Flow Machining (Extrude Hone) //

Abrasive Flow Machining (AFM), also known as extrude honing, is a method of smoothing and polishing internal surfaces and producing controlled radii. A one- or two-way flow of abrasive media is pushed through a work piece, smoothing and finishing rough interior surfaces.

One-way systems push the media through the work piece and then it exits the part. With two-way systems, two vertically opposed cylinders flow the abrasive media back and forth. The process is particularly useful for difficult to reach internal passages, bends, cavities, and edges. This is an inexpensive option for DMLS projects that are not tolerance dependent and have a uniform surface roughness. The success of AFM depends on the degree of preparation of the treated surfaces.

Electroplating //

Electroplating is a process used to grow a thick, protective oxide layer on the surface of a part. Electroplating is a process that uses electrical current to reduce ions of a desired material from a solution and then coat a conductive object with a thin layer of the metal material. Electroplating is primarily used for depositing a layer of metal on a part that will bestow a desired property (e.g., abrasion and wear resistance, corrosion protection, lubricity and aesthetic qualities). Electroplating can also be used to build up thickness on undersized parts. This process is an inexpensive method of improving surface roughness. Reduction of roughness depends on the degree of surface preparation. DMLS parts can also be plated in their raw state and then finished in combination with another method.

Micro Machining Process (MMP) //

Micro Machining Process (MMP) is a mechanical-physical-chemical surface treatment. This process provides highly accurate selective surface finishes. The desired surface finish is obtained by using MMP only on those areas where that particular finish is required. MMP begins with a detailed analysis of the surface of the item to establish the processing parameters required to meet the desired specifications. MMP can distinguish and selectively apply different primary roughness, secondary roughness, and waviness profiles to surfaces. This process has selective application and is ideal for projects requiring precision tolerance finishing to a large number of parts, as well as parts with internal passages that cannot be reached by an alternate method.

CNC Finishing/Machining //

CNC finishing to achieve tight tolerances high quality contoured milling. Detail-oriented precision can be accomplished with CNC lathes. Conventional fixed headstock and Swiss-style CNC lathes can be utilized to support complex operations such as cross drilling, cross tapping, cross milling, slotting, C-axis milling, and off-center work. Proper preparation can yield tolerances as tight as 1 micron or (.00004 in.). Pre-build planning is required to add sufficient material to machined features and surfaces so that tolerances can be met.

DMLS Parts in As Soon As Three-Days / / Get A Quote

What are the Advantages & Disadvantages of DMLS?

DMLS is perfect for projects that require design freedom and rapid turnaround. DMLS can be used to make parts with undercuts, draft angles, cavities, tooling, jigs, rotors, fixtures, and impellers. Multiple pieces such as mountings, sectioned parts, and fasteners can be streamlined into a single part. DMLS has been utilized extensively by the aerospace industry because it allows parts to be produced that were previously impossible to manufacture.

The only real downside to DMLS is the limitation of surface finish. However, any surface roughness can be easily resolved in post-processing.

History of Direct Metal Laser Sintering //

The German firm EOS created Direct Metal Laser Sintering. The timeline of DMLS is as follows:

- 1988 / / Selective Laser Sintering (SLS) was invented by Carl Deckard and paved the way for the introduction of DMLS.

- 1995 / / EOSINT M 250 created an additive manufacturing DMLS system to make metal tools for plastic injection molding. This was the start of rapid tooling.

- 2001 / / A 20 micrometer layer thickness was created by EOS for the DMLS machining to improve part quality.

- 2004 / / EOSINT M 270 introduced a commercial grade fiber laser DMLS system.

- 2007 / / EOSINT introduced EOS Titanium Ti64, a commercial-grade DMLS system for titanium.

DMLS 3D Printing Quote

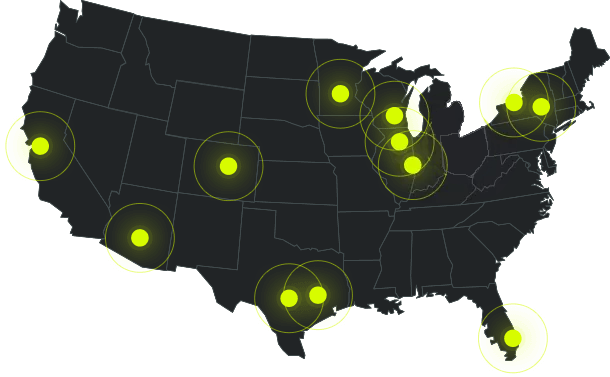

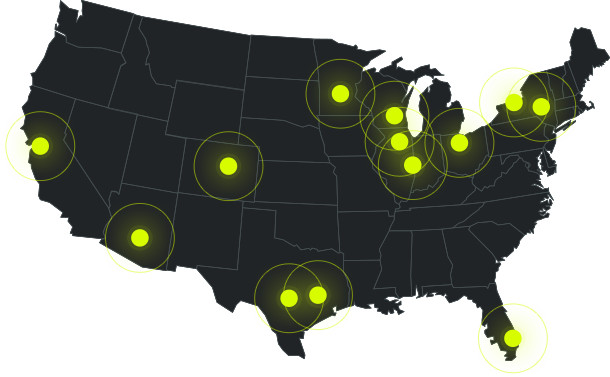

Fathom utilizes a state-of-the-art on-demand online quoting platform that provides customers with unlimited access to quotes and orders for prototyping and production parts. Our team of experts is ready to meet your needs with a wide range of material options. Fathom also offers advanced and expedited services. Companies of all sizes trust Fathom to create medical, consumer, electronics, automotive, and aerospace products. Fathom provided products for nine of the top 10 Fortune 500 companies. Receive fast DMLS quotes and quick turnaround on parts through Fathom’s SmartQuote platform.

Related Topics: