- About Microcut™ Micro Water Jet Cutting

- Cutting Techniques Summary

- Advantages of Micro Water Jet Cutting

- Micro Water Jet Cutting Specifications

- How Does Micro Water Jet Cutting Work?

- Materials Used for Micro Water Jet Cutting

- Micro Water Jet Cutting Applications

- Microcut™ Micro Water Jet Cutting Process Comparison

- Advantage of Microcut™ Micro Water Jet Cutting Over Other Cutting Processes

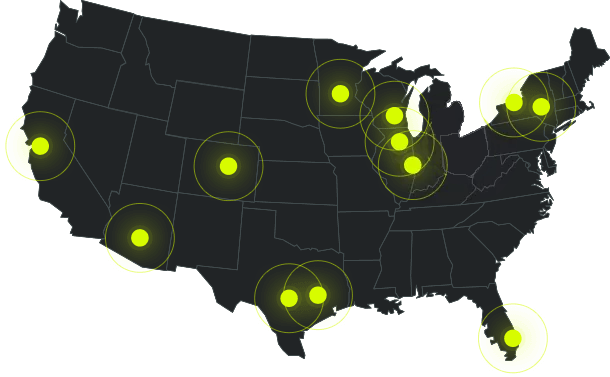

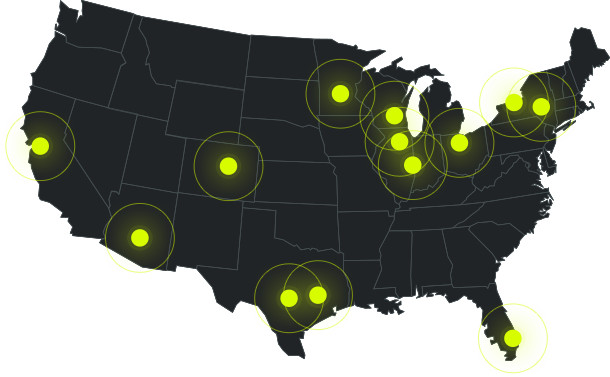

- Which Industries Use Micro Water Jet Cutting

About Microcut™ Micro Water Jet Cutting

Microcut™ micro water jet cutting technology is a revolutionary, abrasive waterjet technology, developed to machine flat parts in thicknesses ranging from 0.001″ to 0.125″ with incredible accuracy. This cold-cutting method produces finished pieces with no burr, no deformations or discolorations, and no heat affected zones. The micro water jet cutting system can also toggle between a pure water setup for softer materials such as silicone or an abrasive configuration for harder materials such as metal. Microcut™ can also cut tight-tolerance features such as holes much faster than Wire EDM technology. Our team of experts is ready to work with you on your micro water jet cutting project. We combine our years of experience with our state-of-the-art Microcut™ machines to deliver accurate micro components of high quality.

Cutting Techniques Summary and How Microcut™ Micro Water Jet Cutting Compares

| Material Thickness | Tolerance | Kerf | Part Volume | Set Up Cost | Lead Time ** | Notes | |

|---|---|---|---|---|---|---|---|

| MICROCUT™ | .0005″ – 0.5″ | 0.0005″ -0.005″ | 0.009″, 0.011″, 0.0196″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, laminates, carbon fiber, ceramics, etc. |

| OMAX WATERJET | Up to 6″ | 0.005″- 0.015″ | .020″/.040″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, carbon fiber, ceramics, etc. Taper up to 59 ° |

| FIBER LASER | AL: 0.250″ SS: 0.375″ CRS: 0.500″ COP: 0.250″ Brass: 0.125″ | 0.002″ – 0.005″ | .008″ | 1 to High-Volume | Low | 6-8 days | Metals – Fast |

| WIRE EDM | 0.001″ – 6″ | 0.0005″ | 0.005″ | 1-200 Is Best | Low | 6-8 days | Conductive Metals, Carbon |

| * CHEM ETCH | 0.005″ – 0.060″ | Is +/- 10% of material thickness, .002″ min. | Equal to metal thickness | 1- Infinity | $350 Min. | 6-8 days | Metal Only. No Burrs. Beveled Edges. Half Etch and Holes. |

* Inner radius should be 100% of material thickness. Outer Radius should be 75% of material thickness.

**Dependent on geometry, volume and material: EXPEDITE options available.

Advantages of Micro Water Jet Cutting

Micro water jet cutting has many benefits, including:

- Incredible accuracy with low setup cost and fast cutting speeds

- Low cutting forces, enabling accurate cutting of extremely delicate features

- No thermal impact or change in material structure

- Superior edge quality

- Minimal burr

- Optimal material usage

- No heat-affected areas

- No minimum thickness requirements

- Cost-effective

- Low waste

- No toxic fumes released

- Little to no post-processing (secondary finishing) required

- Able to cut materials from plastic to hard alloys

- Fast prototype production

- Flexible production, “Just in time” fabrication

- High cutting speeds

- High cutting accuracy

- High surface quality

- Optimal material usage

- Low cutting forces (load)

- No thermal impact (heat)

- No change in material structure

- Narrow kerf width

- Minimal secondary finishing

Micro Water Jet Cutting Specifications

Microcut’s micromachining technology provides higher cutting accuracies and tighter tolerances than standard cutting processes:

- Position accuracy 0.0001 in. (0.003mm)

- Feature and contour accuracy +/- 0.0004 in (0.01mm)

- Kerf width 0.009 in (0.2 mm) min.

- Kerf width 0.0118 in. (0.3 mm) min. with abrasive

- Maximum workpiece size 24 x 39 inches (600 x 1000 mm)

Microcut™ operates without generating heat affected zones, allowing material composition to remain unaltered. Superior edge quality and minimal burr is achieved, resulting in no distortion or stress. In comparison, wire EDM and laser cutting technologies as thermal processes, make it impossible to produce such high precision results without affecting material molecular makeup.

Micro jet water cutting is water jet manufacturing at a micro-level. Water jet cutting allows for the cutting of complex parts with great accuracy. The water jet cutting machine utilizes CNC technology, which facilitates repeatability and precision. The waterjet is attached to a high-pressure pump which forces water through a nozzle to create cuts in the material. The balance between velocity and volume is what allows the machine to cut. The waterjet can shift between a pure water stream and an abrasive water cut, depending on the base material used. Additionally, the water and abrasive substance, powdered garnet, used during water jet manufacturing can be recycled, which increases energy efficiency while lowering costs. Micro jet cutting can produce small components for many industries where there is no room for error, including electronics, aerospace, aviation and more.

How Does Micro Water Jet Cutting Work?

Micro jet water cutting is water jet manufacturing at a micro-level. Water jet cutting allows for the cutting of complex parts with great accuracy. The water jet cutting machine utilizes CNC technology, which facilitates repeatability and precision. The waterjet is attached to a high-pressure pump which forces water through a nozzle to create cuts in the material. The balance between velocity and volume is what allows the machine to cut. The waterjet can shift between a pure water stream and an abrasive water cut, depending on the base material used. Additionally, the water and abrasive substance, powdered garnet, used during water jet manufacturing can be recycled, which increases energy efficiency while lowering costs. Micro jet cutting can produce small components for many industries where there is no room for error, including electronics, aerospace, aviation and more.

Materials Used for Micro Water Jet Cutting

In addition to metals, Microcut™ micro water jet cutting technology is used to cut a wide range of materials, including plastics, glass, ceramic, rubber, silicone and laminated materials. We are open to other materials depending on the needs of our clients. Materials include:

- Metals

- Stainless Steel

- Steel

- Gold

- Silver

- Titanium

- Chromium

- Nickel

- Cast Iron

- Aluminum

- Brass

- Bronze

- Copper

- Alloys

- Glass

- Un-tempered

- Bullet-proof

- Mirror

- Plastic

- Thermoplastics

- Curable

- Elastomer

- Plexiglass

- Stone

- Ceramic

- Granite

- Marble

- Quartz

- Precious Stone

- Miscellaneous

- Rubber

- Kevlar

- Carbon Fiber

- Fiberglass

- Graphite

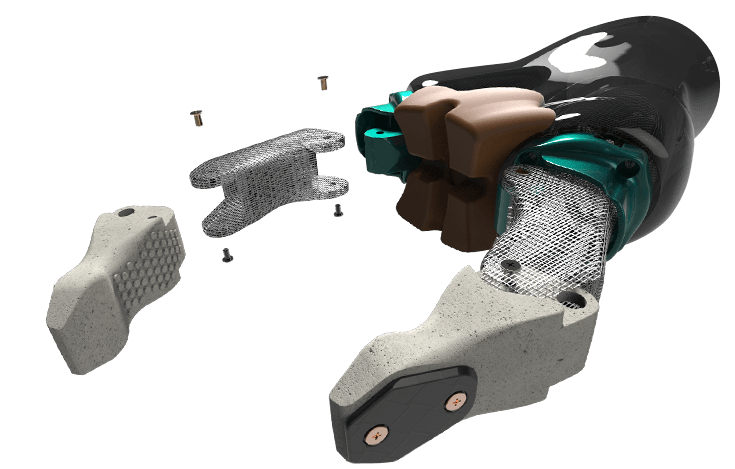

Micro Water Jet Cutting Applications

Micro water jet cutting applications include:

- Airplane components

- Automotive components

- Circuit boards

- Industrial machine parts

- Watchmaking

- Retail

- Electronics

- Instrumentation

- Restoration

Microcut™ Micro Water Jet Cutting Process Comparison

The Microcut™ process was specifically designed to machine two-dimensional, high precision and micro parts with a substantially smaller kerf width (0.006 in.) compared to traditional cutting processes (0.045 in.) that are primarily used to cut or rough out large shapes and/or thicker materials. More competitive with EDM and Laser Cutting, Microcut™ micro water jet cutting cuts without Heat Affected Zones (HAZ).

Advantage of Microcut™ Micro Water Jet Cutting Over Other Cutting Processes

- Fast transition from design to cutting

- Faster setup and cutting speed with higher accuracy

- Minimizes secondary cleaning operations

- Small kerfs

- Ideal for quick prototype, flexible production and proven for high volume production

- Optimum material utilization with CAD/CAM software

Which Industries Use Micro Water Jet Cutting

The micro water jet process is beneficial in industries where there is little to no margin for error, including:

- Aerospace

- Aviation

- Electronics

- Defense

- Medical

- Retail

- Scientific research

- Electronics

- Communications

ISO 9001:2015 Certified + AS9100 Rev. D Certified + ITAR Registered + NIST 800-171 Compliant + ISO 13485 Certified

ISO 9001:2015 Certified + AS9100 Rev. D Certified + ITAR Registered + NIST 800-171 Compliant + ISO 13485 Certified