- About Water Jet Cutting

- Water Jet Cutting Services

- Cutting Techniques Summary and How Water Jet Cutting Compares

- How Does Water Jet Cutting Work?

- Large Format Water Jet Cutting

- Water Jet Cutting Specifications

- No Heat Affected Zones with Water Jet Cutting

- Materials Used for Water Jet Cutting

- Water Jet Cutting Sheet Metal

- What are the Advantages of Water Jet Cutting?

- Water Jet Cutting Applications

- Which Industries Use Water Jet Cutting

- Need Water Jet Cutting for Thin Metal Precision Parts?

- How Water Jet Cutting Companies Differ

- History of Water Jet Cutting

- Water Jet Cost Calculation

- Get a Quote Today for Your Water Jet Cutting Project

About Water Jet Cutting

A water jet cutting machine uses a high-pressure water jet to cut a thin line in the selected material. Water jet cutting is also known as water jet or abrasive jet cutting. Some materials require an additional abrasive, which is added to the jet nozzle. Abrasive water jets are ideal for heavy gauge applications with materials such as aluminum, steel, titanium, Inconel, brass, tool steel, glass, stone or composites. The CNC system uses G-code to direct the water jet and increase precision. Taper control means the cut remains straight throughout the depth of the part, even in thick materials. The water jet cutting process facilitates cutting metal without increasing its temperature or creating a heat affected zone. Water jet cutting can cut holes, complex shapes, and sharp corners. Due to the accuracy of the water jet cutting process, less material waste is made. Water jet cutting is ideal for cutting larger or multiple part projects with rapid water level control for submerged cutting and a large work envelope.

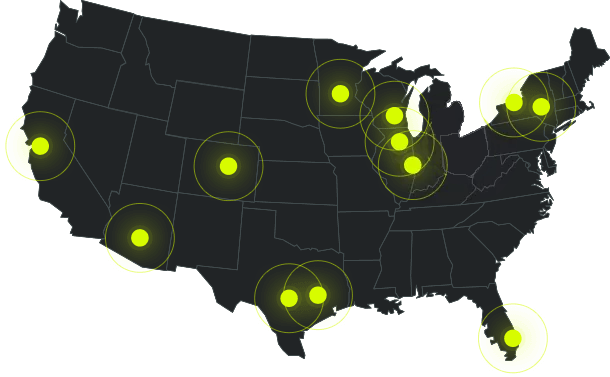

Water Jet Cutting Services

Fathom provides nationwide access to precision water jet cutting services using state-of-the-art cutting machines. Whatever your desired outcome, we have a cutting solution to meet the goal.

Cutting Techniques Summary and How Water Jet Cutting Compares

| Material Thickness | Tolerance | Kerf | Part Volume | Set Up Cost | Lead Time ** | Notes | |

|---|---|---|---|---|---|---|---|

| OMAX WATERJET | Up to 6″ | 0.005″- 0.015″ | .020″/.040″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, carbon fiber, ceramics, etc. Taper up to 59 ° |

| MICROCUT™ | .0005″ – 0.5″ | 0.0005″ -0.005″ | 0.009″, 0.011″, 0.0196″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, laminates, carbon fiber, ceramics, etc. |

| FIBER LASER | AL: 0.250″ SS: 0.375″ CRS: 0.500″ COP: 0.250″ Brass: 0.125″ | 0.002″ – 0.005″ | .008″ | 1 to High-Volume | Low | 6-8 days | Metals – Fast |

| WIRE EDM | 0.001″ – 6″ | 0.0005″ | 0.005″ | 1-200 Is Best | Low | 6-8 days | Conductive Metals, Carbon |

| * CHEM ETCH | 0.005″ – 0.060″ | Is +/- 10% of material thickness, .002″ min. | Equal to metal thickness | 1- Infinity | $350 Min. | 6-8 days | Metal Only. No Burrs. Beveled Edges. Half Etch and Holes. |

* Inner radius should be 100% of material thickness. Outer Radius should be 75% of material thickness.

**Dependent on geometry, volume and material: EXPEDITE options available.

How Does Water Jet Cutting Work?

A water jet cutting machine is used to produce flat-cut parts. The machine is controlled using CNC technology, which allows for repeatability of movement and greater precision. The waterjet can be used to cut softer materials such as rubber, wood, or foam. For hard materials such as sheet metal, an abrasive substance is added to the nozzle. The machine can switch between water cutting and abrasive water cutting depending on the application. The water jet is attached to a high-pressure pump which forces water through a nozzle to create precise cuts. The balance between velocity and volume is what facilitates the cut. When an abrasive water cut is needed, the abrasive substance is mixed with the water stream. The water and powdered garnet used during the process can be recycled and reused, which reduces costs while increasing energy efficiency.

Large Format Water Jet Cutting

Abrasive water jets are ideally suited for heavy gage applications with materials such as aluminum, steel, titanium, Inconel, brass, tool steel, glass, stone or composites. Ideal for cutting larger or multiple part projects with rapid water level control for submerged cutting and a large work envelope. Our tools and technology are specialized to handle large format water jet cutting to better support your large format needs.

Water Jet Cutting Specifications

Ideal for cutting larger or multiple part projects with rapid water level control for submerged cutting and a work envelope offering X-Y cutting travel from 13′ 4″ up to 26′ 8″ x 6′ 8″ (4,064 – 8,128 mm x 2,032 mm).

Water jet technology provides higher cutting accuracies and tighter tolerances than standard cutting processes:

- Position accuracy ±0.003” (±0.076 mm)

- Repeatability ±0.003” (±0.076 mm)

- Kerf width 0.040″ (01.02 mm)

- Mini Head Kerf width 0.020″ (0.51 mm)

- Maximum work piece size 13’4″x 6’8″ to 26′ x 6’8″ inches (4,064 mm x 2,032 mm to 8,128 mm x 2,032 mm)

No Heat Affected Zones with Water Jet Cutting

Water jet technology is used to cut a wide range of materials and can go up to 8″ in thickness. Great for heavy or structural components like helicopter rotor assembly parts or for any design part application calling for thick material and tight feature tolerance.

Materials Used for Water Jet Cutting

Materials available for water jet cutting include:

- Aluminum

- Steel

- Titanium

- Inconel

- Brass

- Tool steel

- Composites

Water jet cutting can also be used on additional materials.

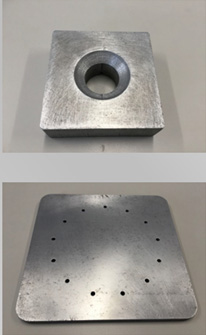

Waterjet Cutting Sheet Metal

Waterjet cutting is ideal for sheet metal projects with thick material or ones that have patterns with large tolerances. Waterjet cutting allows the metal to remain flat through the process. There are a lot of factors that come into play specific to the end cost of your cutting project but waterjet cutting for sheet metal is one to consider.

What are the Advantages of Water Jet Cutting?

Water jet cutting is suitable for many applications, making it one of the most versatile manufacturing processes. In addition to its versatility, water jet cutting has the following benefits:

- Used with a wide variety of material types

- No thermal impact or change in the material structure

- Incredible accuracy with low setup cost

- Variable speed to maintain the vertical edge quality

- Minimal burr and secondary finishing

- Minimal kerf

- Efficient material usage

- Highly durable parts

- Cost-effective

- Quick turnaround

- Produce complex shapes

Water Jet Cutting Applications

Many parts are made using the water jet cutting manufacturing process:

- Engine components

- Airplane parts

- Truck bed liners

- Bumpers

- Copper head gaskets

- Automotive interior trim

- Electrical enclosures

- Cable stripping

- Circuit boards

- Signage

- Stained glass

- Healthcare products

- Beverage manufacturing equipment

- And much more

Which Industries Use Water Jet Cutting

The water jet cutting process is suitable for a wide variety of industries, including:

- Aerospace

- Automotive

- Electronics

- Medical

- Architectural/Design

- Food Production and Processing

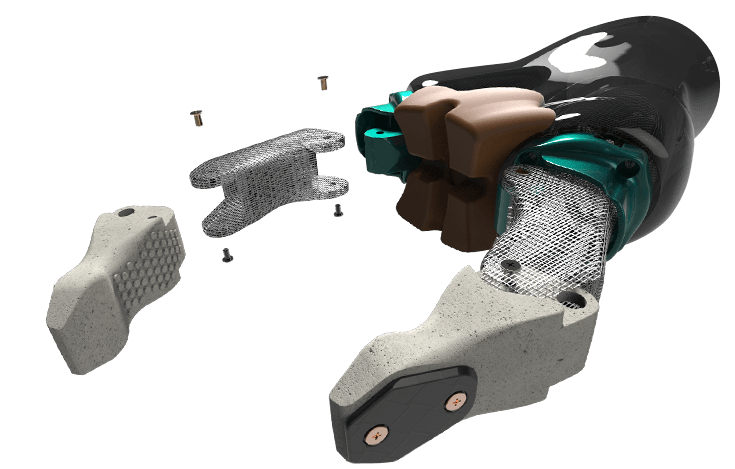

Need Water Jet Cutting for Thin Metal Precision Parts?

Microcut™ micro water jet cutting technology is a revolutionary, abrasive waterjet technology, developed to machine flat parts in thicknesses ranging from 0.001″ to 0.125″ with incredible accuracy. Micro jet water cutting is water jet manufacturing at a micro-level. Water jet cutting allows for the cutting of complex parts with great accuracy. The water jet cutting machine utilizes CNC technology, which facilitates repeatability and precision. The waterjet is attached to a high-pressure pump which forces water through a nozzle to create cuts in the material. The balance between velocity and volume is what allows the machine to cut.

How Water Jet Cutting Companies Differ

Different water jet cutting companies can differ based on the specific type and volume of water jet cutting they offer. Each will come with specific expertise and may specialize in different industries. Fathom provides nationwide access to precision water jet cutting services using state-of-the-art cutting machines. Whatever your desired outcome, we have a cutting solution to meet the goal.

History of Water Jet Cutting

In the 1930s, the first water jet cutting devices used a low-pressure stream and were initially used to cut paper. Ten years later, higher-pressure waterjets were made to cut parts for the aviation and automotive industries. During the 1950s, the first liquid jet machine was made by John Parsons. In the 1970s, commercial waterjet cutting machines were introduced by the Bendix Corporation. Abrasive waterjet nozzles using ceramic tungsten carbide composite were patented and introduced by the Boride Corporation. During the 1990s, the OMAX Corporation patented Motion Control Systems. Finally, in the 2000s, zero tapper waterjets were made to increase precision cutting, and six-axis machines improved waterjet cutting overall.

Water Jet Cost Calculation

Water jet cutting costs can vary based on the type of material being cut, volume and other project criteria. Most cost calculations are calculated based on the time a job takes on the water jet cutting machine. Of course this is dependent on the variables mentioned above. So in the end, water jet cutting cost calculations can vary greatly.

Get a Quote Today for Your Water Jet Cutting Project

Our experts are ready to talk to you about your water jet cutting part. Get started today with an online quote.

ISO 9001:2015 Certified + AS9100 Rev. D Certified + ITAR Registered + NIST 800-171 Compliant + ISO 13485 Certified

ISO 9001:2015 Certified + AS9100 Rev. D Certified + ITAR Registered + NIST 800-171 Compliant + ISO 13485 Certified