- Create Your Rapid Prototype with Fathom

- What is Rapid Prototyping?

- Advantages of Rapid Prototyping

- Rapid Prototyping Applications

- How Does Rapid Prototyping Work?

- What is Additive Manufacturing?

- Additive Manufacturing Technologies Used for Rapid Prototyping

- What is The Difference Between Rapid Prototyping & 3D Printing?

- History of Rapid Prototyping

- Rapid Prototyping Questions Answers

- Get a Quote for Your Rapid Prototyping Project

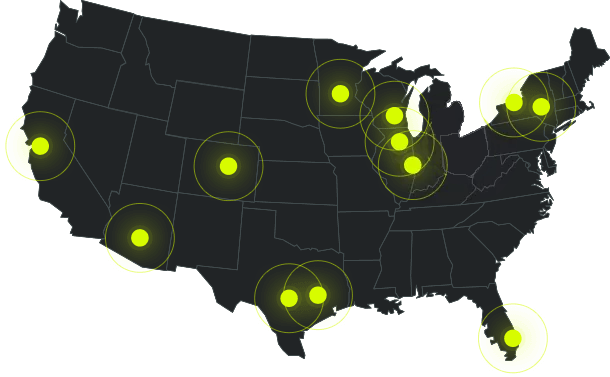

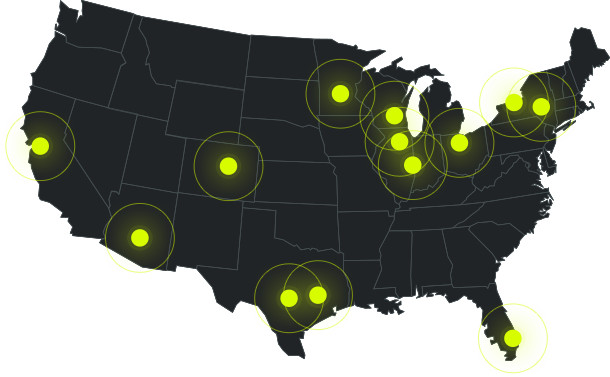

Rapid Prototyping with Fathom

For brands looking for reliable rapid prototyping services, Fathom offers a wide range of additive manufacturing rapid prototyping technologies that can help your team create a prototype as soon as possible. There are many different ways you can create a prototype. The experts at Fathom can guide you through the various processes to determine the best solution to suit the design. Thanks to advancements in 3D printing processes, rapid prototypes can be produced quickly and within a specific budget. Fathom offers high quality plastic and metal for your rapid prototype as well as expedited services to help you get your prototype even faster.

What is Rapid Prototyping?

Rapid prototyping is the quick production of a part or model based on a 3D Computer-Aided Design (CAD). The rapid prototype is typically made using an additive manufacturing or 3D printing technology. In the past, rapid prototyping was achieved using the same or similar process as the final product, which led to costly tooling and setup. Thanks to developments in additive manufacturing, rapid prototyping can be cost-effective and quick.

Advantages of Rapid Prototyping

There are many benefits to rapid prototyping. These include //

- Communicate a Concept Effectively with a Physical Product

- Test Multiple Versions of a Design

- Catch Design Flaws Early

- Reduce Waste

- Test Fit, Appearance & Functionality

- Save Money As No Tooling or Setup Is Required

Rapid Prototyping Applications

Rapid prototyping can be applied across multiple industries using various technologies and materials, including //

- Workable Prototype Proves A Design Is Successful

- Verify Functionality, Fit & Form Before Large-Scale Production

- Provide Physical Example For Investors

- Use Prototype To Gain Customer Feedback & Collect Data

- Concept Models

- Test Fixtures & Assembly

- Marketing Mockups

- Initial Design

- Production Tooling

- Mockups for Production Planning

These are just a few of the possibilities with rapid prototyping. There are many more opportunities that may be unique to your specific project.

How Does Rapid Prototyping Work?

To begin the rapid prototyping process, a design is first created using a Computer-Aided Design (CAD) software or a scan of a model is taken. The 3D printing machine uses the design as a blueprint, printing each layer of the product successively. Depending on the technology chosen, rapid prototypes can be produced within a matter of hours or days.

What is Additive Manufacturing?

Additive Manufacturing (AM) constructs 3D models by layering materials. The object is made by following specifications laid out by a CAD design or digital 3D model. AM may use a number of materials from polymer, metal, glass, ceramic, foam, gel and more. Applications of additive manufacturing include industrial tooling, customized products, production parts, a visualization tool in design and more.

Additive Manufacturing Technologies Used for Rapid Prototyping

- Stereolithography //SLA cures photopolymer resin with an ultraviolet laser. The laser traces a shape dictated by the original file across the surface of the resin bath. The resin touched by the laser hardens, then the build platform descends in the resin bath and the process is repeated until the entire part is complete.

- Selective Laser Sintering //SLS uses a blade to spread a thin layer of powder over the build volume. A laser sinters the cross-section of the part, fusing the powder together. The z stage then drops one layer and the process repeats until the build is finished. Parts are then excavated from the build powder-cake and bead blasted. The unused powder in the build envelope acts as the support structures, so no support removal is necessary.

- PolyJet //PJ is a photopolymer-based jetting process that distributes material droplets layer-by-layer onto a build platform (immediately cured by a flash of UV light). At the end of the build process, the object is fully cured and can be handled immediately without post-curing. This technology includes the use of a gel-like support material, designed to enable complicated geometries (removed by soaking and/or water jetting).

- Multi Jet Fusion //MJF technology builds parts by laying down a thin layer of powder on a print bed over and over. The inkjet array in the print carriage sweeps over the print bed, jetting two agents downward—a fusing agent, printed where the powder will fuse together, and a detailing agent that is used to reduce fusing at the part boundary to achieve greater detail.

- Fused Deposition Modeling //FDM is a filament-based additive technology distributed by a moving print head that extrudes a heated thermoplastic material in a pattern layer-by-layer onto a build platform. This technology includes use of support material to create supportive structures that are removed by force or solution.

- Direct Metal Laser Sintering //Metal 3D printing, also known as Direct Metal Laser Sintering (DMLS) and Direct Metal Laser Melting (DMLM) is an additive layer technology. A metal 3D printer utilizes a laser beam to melt 20-60-micron layers of metal powder on top of each other. Powdered metal is spread across the entire build platform and selectively melted to previous layers. This additive process allows metal parts to be grown out of a bed of powdered metal. The process is like other polymer-based 3D printers that use powder bed fusion.

What Is The Difference Between Rapid Prototyping & 3D Printing?

The terms rapid prototyping and 3D printing are sometimes used interchangeably. 3D printing is a technology or process in which a physical part is made based on a 3D design or model. Rapid prototyping is the application of additive manufacturing technologies. In other words, you may select an additive manufacturing process, such as 3D printing, to create your rapid prototype.

History of Rapid Prototyping

Stereolithography was invented in 1987, which facilitated rapid prototyping. Stereolithography uses UV-sensitive polymers and a laser to create a 3D part. Additional rapid prototyping processes were developed including Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM) and more. In 1992, Stratasys introduced a 3D prototyping system using Fused Deposition Modeling. In 2000, Objet introduced PolyJet, which can also used for rapid prototyping.

Rapid Prototyping Questions Answers

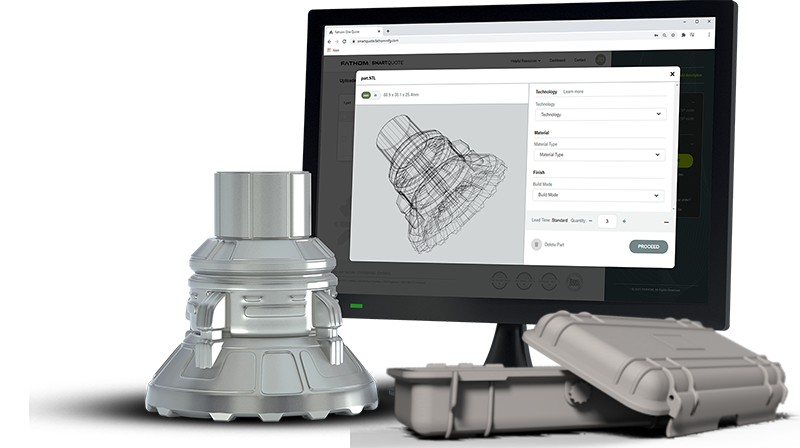

Q //How Can I Get A Quote For A Rapid Prototype?

A //Receive an instant quote through the SmartQuote platform.

Q //What Is The Difference Between Rapid Tooling & Rapid Prototyping?

A //Parts made for rapid tooling are used in another manufacturing process as a tool, whereas, parts made for rapid prototyping are used in a similar fashion as the final product.

Q //What Other Terms Are Used For Rapid Prototyping?

A //3D printing, additive manufacturing, layered manufacturing and digital prototyping are other related terms for rapid prototyping.

Q //What Is The Difference Between Additive Manufacturing & Layered Manufacturing?

A //There is no difference between the two. They are the same.

Q //What Is An STL File?

A //Originally used by SLA systems, STL stands for Standard Triangle Language. It is a file format commonly used by different additive manufacturing or 3D printing technologies. An STL file communicates the surface geometry of a part to the machinery. The file is a triangular facet representation in which the surfaces of the part are modeled as triangles that share edges and vertices.

Get a Quote for Your Rapid Prototyping Project

Get a 3D printing quote instantly on any 3D project today.