What is STEP Technology?

STEP technology is the first viable alternative to injection molding. Additive lead-time for low volume IM quantity (hundreds/thousands of parts in days) vs months

STEP technology is the first viable alternative to injection molding. Additive lead-time for low volume IM quantity (hundreds/thousands of parts in days) vs months

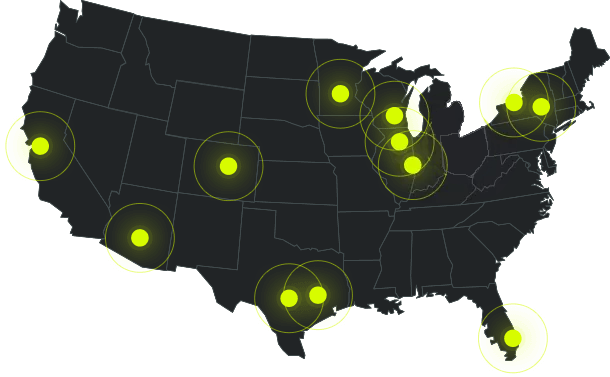

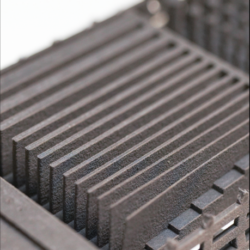

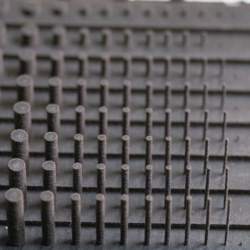

It enables the additive production of ABS parts within hours or days instead of the typical several-month lead time for traditional injection molding parts. SVP offers higher part quality with both repeatability and scalability. Additionally, the Evolve SVP™ delivers a throughput that is 10 times faster than any other industrial additive printer.

STEP technology was developed for speed and scaled to offer a manufacturing solution for low- to mid-volume thermoplastic parts and created specifically for production manufacturing.

Since Evolve STEP Technology relies on digital rather than physical molds, Fathom is able to produce the exact same part to the exact same specs with the Evolve SVP system.

Repeatability without compromising throughput or flexibility.

Evolve STEP™ technology eliminates tooling, mold storage, mold modifications and reduces logistics.

These technologies can meet the rigorous demands of customers in the aerospace, automotive, industrial, medical, and consumer sectors, where products are highly engineered with precise specifications.

The benefits of using STEP technology below provide many advantages. Whether you need small or delicate parts, production quantities or for prototyping- STEP technology is well-suited for your needs.

Here are some key benefits below:

A customer came to Fathom with a complex part that required complex tooling for a racetrack-style scoreboard panel. Fathom recommended STEP technology, a groundbreaking 3DP technology that is able to print injection mold-like parts in days instead of weeks, with similar functional properties and surface finish of injection molded ABS.

Results //

With the deployment of STEP technology, quick and smooth DFAM (Design for Additive Manufacturing) for clip designs saved time and money.

43% Cost Savings | 63% Time Savings

Measures down to ~0.2 mm

Designed to 0.2 mm

Multi-part, intricate build

Example // Check Valves

Example // Bracket Sets

Example // Threads

Example // Manifold

Example // Electronics

Units measured in mm

Capabilities typically material-dependent; values cited are for ABS or most similar option

* Injection molding capabilities vary dramatically; typical small-mid size part capabilities shown

Want to try out STEP additive for yourself? Fill out the form below and a Fathom expert will reach out to you.