- What is FDM Printing?

- How Does a Fused Deposition Modeling (FDM) 3D Printer Work?

- What Materials are Used in Fused Deposition Modeling?

- What are the Advantages of FDM?

- What Industries use FDM?

- Why Choose FDM?

- What is the Difference Between FFF & FDM?

- Who Invented Fused Deposition Modeling?

- Get a FDM 3D Printing Quote

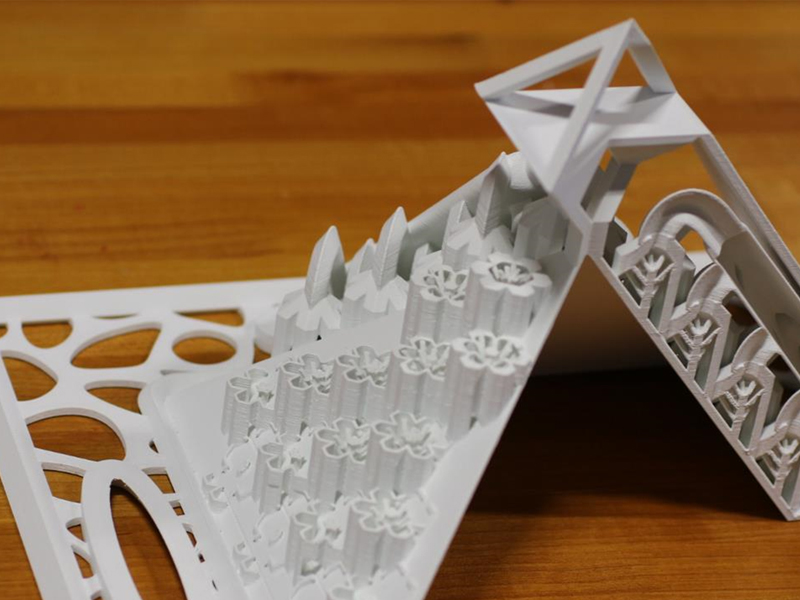

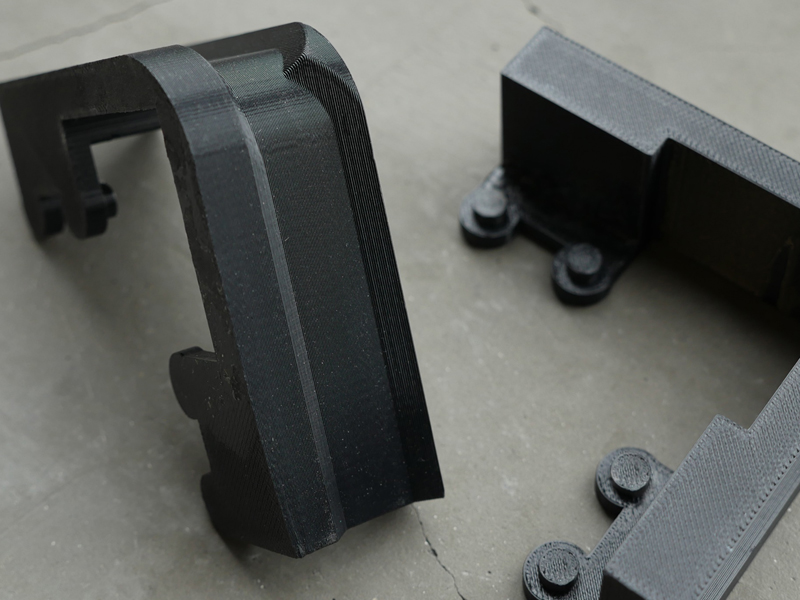

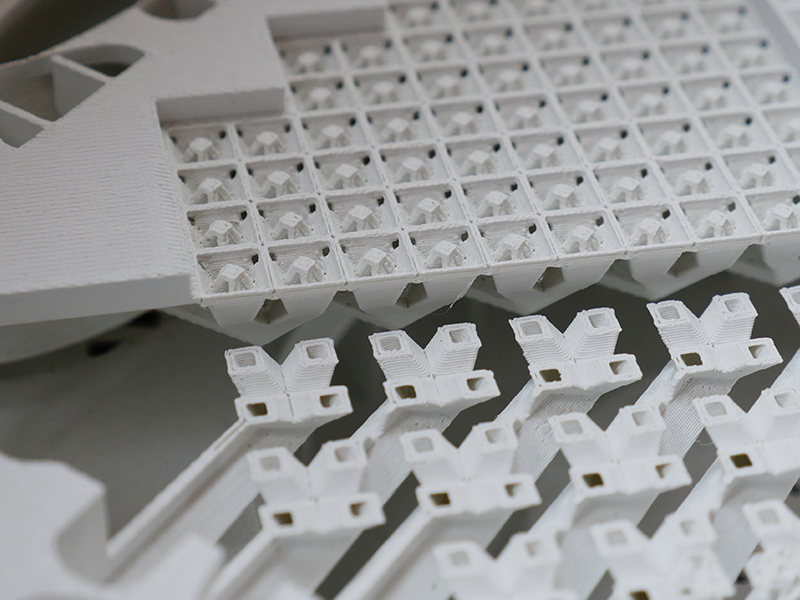

Fused Deposition Modeling (FDM) is ideal for building concept models, functional prototypes, and end-use parts using standard, engineering-grade, or high-performance thermoplastics. FDM uses many of the same raw materials used in the injection molding process.

What is FDM Printing?

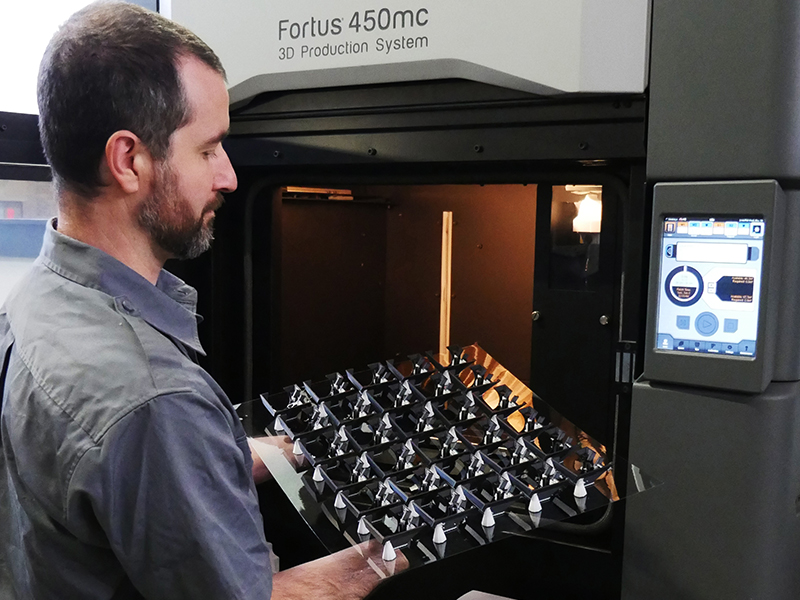

FDM is a filament-based additive technology. Material is distributed by a moving print head that extrudes a heated thermoplastic in a pattern, layer-by-layer, onto a build platform. This technology includes the use of support material to create supportive structures that are removed after completion by force or solution. FDM is the best choice for jigs and fixtures, molds, tooling, and other functional parts that require durability and resistance. Additional examples of FDM include medical tissue engineering, rapid prototyping, and production applications.

How Does a Fused Deposition Modeling (FDM) 3D Printer Work?

The FDM process starts with a computer-aided design (CAD) file. The CAD file acts as a set of instructions or blueprints for the machine. An FDM printer will use two types of materials to build the part — one for modeling and the other for support. Filaments are unwound from a coil and fed into an extrusion nozzle. The nozzle is heated to melt the material and can be moved in horizontal and vertical directions. The nozzle is controlled by a computer-aided manufacturing (CAM) software package. Parts are built by extruding small beads of thermoplastic material to form successive layers. Each layer hardens immediately after extrusion from the nozzle. Once the piece is made, the support structures must be removed by force or dissolved in solution. The size and complexity of the part design will impact the amount of time it will take to complete the build process.

What Materials are Used in Fused Deposition Modeling?

FDM printers can use a variety of materials. The printer is fed filament from a spool, usually a blend of thermoplastic and organic material. Several materials are available with different trade-offs between strength and temperature properties. FDM technology can be used with Acrylonitrile butadiene styrene (ABS) polymers, polycarbonates, polycaprolactone, polyphenyl sulfones, waxes, and more. The material selected will affect the accuracy and properties of the part produced as well as the cost.

AMT PostPro3D Finishing / /

AMT’s PostPro3D technology is an automated post processing solution for smoothing FDM 3D printed parts. PostPro3D achieves a high quality surface finish that matches injection molding techniques while using 3D printing processes. This technology reduces lead-time, cost of manufacture, and operational and maintenance costs while providing the ‘missing piece’ in the digital manufacturing chain.

Talk to an expert at Fathom today to take your parts to the next level using AMT PostPro3D for post processing.

FDM 3D Printed Parts and Images

| MATERIALS | DESCRIPTION |

|---|---|

| TPU 92A (thermoplastic polyurethane elastomer) |

|

| Antero™ 800NA (polyetherketoneketone) |

|

| ULTEM™ 1010 resin (polyetherimide) |

|

| ULTEM™ 9085 resin (polyetherimide) |

|

| FDM Nylon 12™ (polyamide 12) |

|

| FDM Nylon 12CF™ (polyamide 12CF) |

|

| PC (polycarbonate) |

|

| PC-ISO™ (polycarbonate – ISO 10993 USP Class VI biocompatible) |

|

| PC-ABS (polycarbonate – acrylonitrile butadiene styrene) |

|

| ASA (acrylonitrile styrene acrylate) |

|

| ABS-ESD7™ (acrylonitrile butadiene styrene – static dissipative) |

|

| ABS-M30™ (acrylonitrile butadiene styrene) |

|

-

0.005 inch (0.127 mm) layer thickness not available for Stratasys F900.

-

See individual material spec sheets for testing details.

-

Annealed

-

Actual surface resistance may range from 109 to 106 ohms, depending upon geometry, build style and finishing techniques.

-

Available only on the Stratasys F370

Download the FDM Material Specification PDF and consult a Fathom expert for details on different materials.

For additional flexible 3D printing options // TPU 88A for SLS, PolyJet, and Urethane Casting

Order Material Samples // Keychains and Kits

What are the Advantages of FDM?

FDM technology can produce parts and prototypes using engineering grade plastics. FDM thermoplastic parts are strong, durable, and dimensionally stable. FDM parts can be used for advanced conceptual models, functional prototyping, production parts, and manufacturing tools. Modern FDM 3D printing machines possess large build envelopes capable of producing larger pieces at higher quantities than other additive manufacturing technologies. FDM printers are so efficient that they can eliminate many of the steps necessary with traditional manufacturing. As a result, overhead costs are reduced and there is a quicker turnaround. Customers often use FDM technology due to the wide selection and lower price of materials. Multiple different types of material can be used simultaneously in the FDM process. Some additional benefits of FDM include / /

- Suitable For Rapid Prototyping, Modeling, and Production

- No Assembly Required — All Parts Can Be Produced As A Single Object

- Impact Resistance and Toughness

- Lightweight Product

What Industries use FDM?

FDM parts are durable, chemical resistant, and can endure extreme conditions, making them ideal for testing and end-use parts. As FDM technology continues to advance, more and more industries have adopted the technology, including / /

- Medical and Dental

- Automotive and Antique Automotive

- Jewelry and Art

- Custom Automation

- Aerospace

- Architecture

- Pharmaceutical

- Health and Beauty

- Food and Beverage

- Packaging

Why Choose FDM?

FDM uses many of the same materials used in injection molding. FDM parts can be used to test a design before transitioning to the production process. This allows designers and engineers to identify any issues and make improvements early in the design process. The ability to test early saves a lot of time and money in the long run. A functional prototype can be produced within a few hours or days, depending on the complexity of the part. Having a functional prototype reduces the time to market and helps maximize overall product performance.

FDM technology also presents an opportunity to create custom tooling and fixtures. This allows a customer the flexibility to take on new projects while lowering costs and risks in a timely manner — much quicker than traditional production. Injection molding is an extremely cost effect manufacturing process but the up front cost for mold tooling can be cost prohibitive when running only a few parts for testing. Printing with FDM will allow engineers the ability to create and test a part without the cost and time associated with injection mold making.

A low-volume production run is easy with FDM. There is no minimum quantity requirement; make as much or as little as is required. Production can start as soon as a Computer-Aided Design (CAD) design file is available and translated to the 3D printing machine.

What is the Difference Between Fused Filament Fabrication and Fused Deposition Modeling?

Fused Filament Fabrication (FFF) and Fused Deposition Modeling (FDM) are different in name only. Both processes are the same and the two terms can be used interchangeably. Fused Deposition Modeling was initially invented and trademarked by Stratysys, Inc. in 1988. The patent did not expire until 2009. Other 3D printing companies used the term Fused Filament Fabrication to avoid trademark violations.

Who Invented Fused Deposition Modeling?

Scott Crump, founder of Stratasys, invented FDM technology nearly 30 years ago using the same production-grade thermoplastics found in traditional manufacturing processes. FDM is ideal for applications that require tight tolerances, toughness, and environmental stability. The materials available for FDM also meet applications requiring specialized properties such as electrostatic dissipation, translucence, biocompatibility, VO flammability, or Fire Smoke Toxicty ratings.

FDM Timeline / /

- 1989 Scott Crump patents Fused Deposition Modeling (FDM)

- 1991 Stratasys commercializes FDM

- 2008 Stratasys offers high-performance ULTEM 9085 for its 900MC and 400MC FDM machines

- 2009 First FDM patent expires

- 2011 Beginning of FDM 3D desktop printers

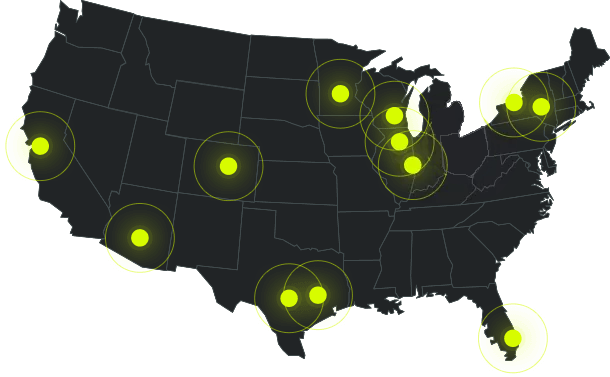

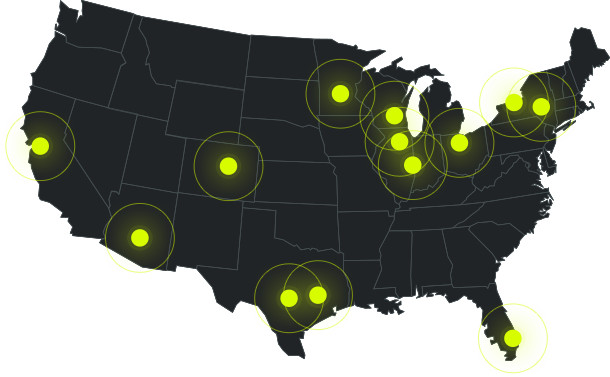

Get a FDM 3D Printing Quote from Fathom

Quickly get a quote in as soon as one hour on any FDM 3D printing project today with our SmartQuote platform.